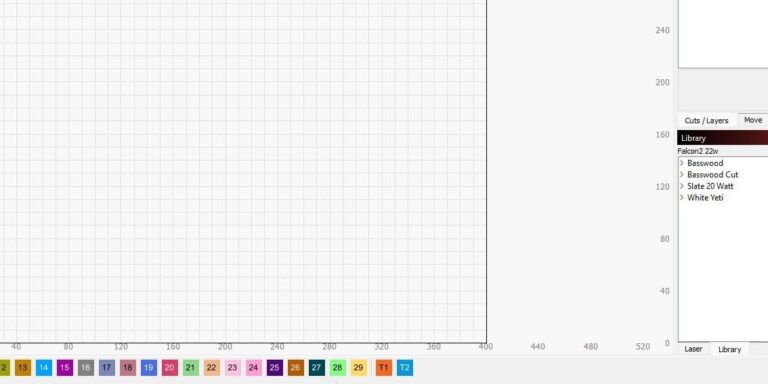

Learn more about the differences between laser engraving and traditional cutting methods.

Laser engraving and traditional cutting methods are both used for material processing, but they differ significantly in how they operate, the results they produce, and their applications. Here’s a breakdown of the key differences:

1. Technology and Process

- Laser Engraving:

- Process: Laser engraving uses a focused beam of light (laser) to vaporize or burn the surface of a material. The laser’s intensity is carefully controlled to engrave designs, text, or patterns onto various materials, such as wood, metal, glass, plastic, and leather.

- Precision: Extremely high precision is achievable, allowing for intricate and detailed designs. The laser can be controlled digitally, enabling complex patterns and repeatability.

- No Physical Contact: The laser beam does not physically touch the material, reducing wear and tear on the tool and minimizing material deformation.

- Traditional Cutting Methods:

- Process: Traditional cutting involves physical tools such as saws, knives, or chisels to remove material. The method varies depending on the material and the desired outcome. Common methods include sawing, drilling, and milling.

- Precision: Precision depends on the tool and the skill of the operator. Fine detail work is possible but often more challenging to achieve consistently.

- Physical Contact: The tool makes direct contact with the material, which can lead to wear on both the tool and the material, potentially causing distortion or inaccuracies.

2. Materials

- Laser Engraving:

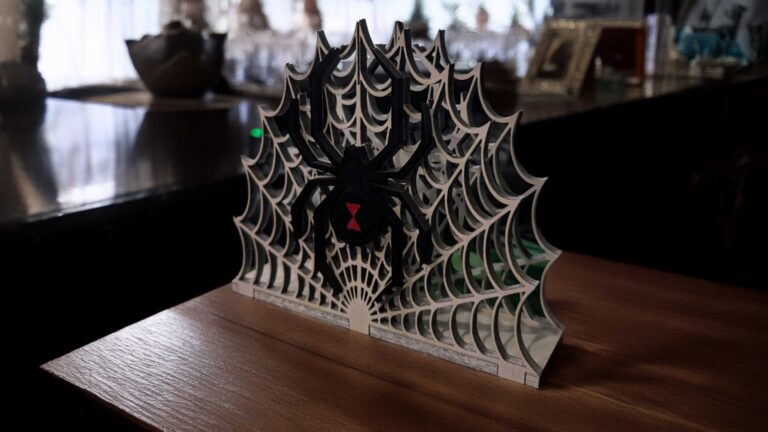

- Versatility: Works on a wide range of materials, including wood, acrylic, glass, metals (with or without coatings), plastics, and even organic materials like leather and stone.

- Material Thickness: Ideal for engraving rather than cutting through thick materials. However, it can cut through thinner materials like paper, wood, or acrylic.

- Traditional Cutting Methods:

- Material Suitability: Specific tools are required for different materials (e.g., metal saws for metal, wood saws for wood). Not all tools work across different materials.

- Material Thickness: Can handle a variety of material thicknesses, especially in cutting operations. Traditional cutting tools are more suited for cutting through thick materials.

3. Applications

- Laser Engraving:

- Common Uses: Engraving logos, serial numbers, barcodes, decorative designs, and personalized items. Widely used in industries such as electronics, jewelry, signage, and manufacturing.

- Customization: Ideal for one-off, custom, or small-batch production runs where high precision is required.

- Traditional Cutting Methods:

- Common Uses: Cutting, shaping, and fabricating materials in construction, manufacturing, woodworking, metalworking, and crafts. Used for both simple cuts and complex shapes depending on the tool.

- Customization: Often used for larger production runs, but customization can be less efficient compared to digital methods like laser engraving.

4. Speed and Efficiency

- Laser Engraving:

- Speed: Generally faster for engraving intricate designs, as the process is automated and can be easily repeated. The speed depends on the material and the complexity of the design.

- Setup Time: Minimal setup time, especially for digital files. Once programmed, the laser can quickly move from one job to the next.

- Traditional Cutting Methods:

- Speed: Cutting speed depends on the material and the tool used. Complex shapes or intricate details may require slower, more careful work.

- Setup Time: Can be longer, especially if jigs or specific tools need to be prepared for the task. Manual adjustments may be necessary for each job.

5. Safety and Environmental Impact

- Laser Engraving:

- Safety: Requires proper ventilation and safety measures to avoid exposure to fumes or laser radiation. No physical contact reduces the risk of injury from moving parts.

- Environmental Impact: Potential emissions from vaporized materials need to be managed. Some materials may release harmful fumes when engraved.

- Traditional Cutting Methods:

- Safety: Physical tools present a risk of injury from sharp edges, moving parts, or tool kickback. Safety gear like gloves and goggles are often required.

- Environmental Impact: Generates physical waste (e.g., sawdust, metal shavings). Disposal or recycling of these byproducts may be necessary.

6. Cost and Accessibility

- Laser Engraving:

- Initial Cost: Higher initial investment for laser equipment. However, the cost is balanced by lower maintenance and running costs over time.

- Accessibility: More accessible with advancements in technology, but still requires specific knowledge to operate effectively.

- Traditional Cutting Methods:

- Initial Cost: Lower initial cost for tools, but higher long-term maintenance as tools wear out and need replacement.

- Accessibility: Widely accessible and requires less specialized training, though skill is needed for high-quality results.