Mastering Precision: Designing Effective Jigs for Laser Cutting Projects

In laser cutting endeavors, achieving precision and consistency is of utmost importance. Whether you are engaged in creating a collection of detailed designs or aiming to produce identical cuts repeatedly, a dependable setup is essential. This is where the use of jigs becomes significant. In this article, we will examine the role of jigs in laser cutting and provide guidance on designing your own to ensure accurate and repeatable outcomes.

Why Jigs Matter

A jig is a custom-made tool that holds your material in place, guiding the laser cutter to make consistent cuts or engravings. Jigs are especially useful when you need to produce multiple pieces with exact dimensions, or when working with irregularly shaped objects that need precise alignment.

Benefits of Using Jigs:

- Accuracy: Jigs ensure that your material is positioned correctly every time, which is essential for achieving perfect cuts or engravings.

- Efficiency: Once your jig is set up, you can quickly load and unload materials, speeding up the production process.

- Consistency: With a jig, every piece you cut will be identical, reducing waste and ensuring quality.

- Versatility: Jigs can be designed to accommodate various shapes and sizes of materials, making them a versatile tool in your workshop.

Tips for Designing Your Own Jig

Understand Your Project Needs: Before designing a jig, consider the specifics of your project. What material are you working with? What shapes do you need to cut? How many pieces will you produce? These factors will influence your jig’s design.

Material Selection: Choose a sturdy, durable material for your jig. Wood and acrylic are popular choices, as they are easy to cut and can withstand repeated use. Make sure the material is thick enough to hold your workpieces securely.

Precision is Key: Use your laser cutter to create the jig itself, ensuring that the slots and guides are perfectly aligned. This will allow for accurate positioning of your materials.

Incorporate Registration Marks: Adding registration marks to your jig can help align the material and ensure consistency, especially when working on two-sided projects or multi-step processes.

Test and Adjust: After creating your jig, test it with a few practice cuts. Make any necessary adjustments to improve the fit and accuracy before starting your production run.

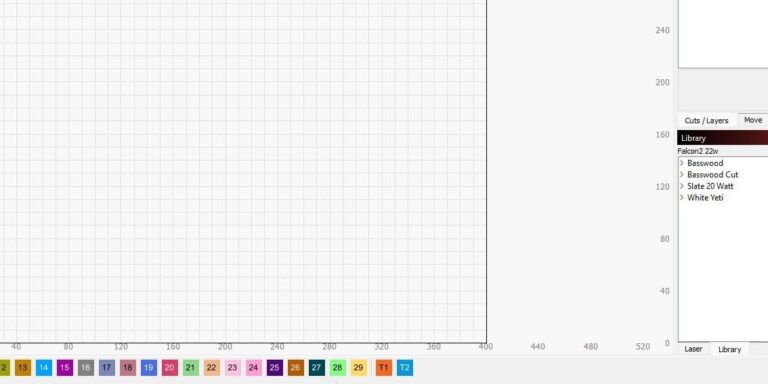

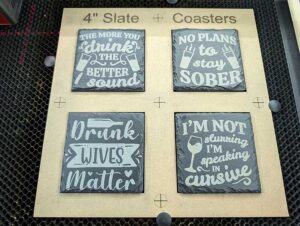

Here’s a practical example of a jig specifically designed for laser cutting. In this case, the jig was crafted to securely hold wooden pieces in place during the engraving process. As shown in the image below, the jig incorporates precisely cut slots and fixtures that align perfectly with the dimensions of the material, ensuring that each piece remains firmly positioned. This prevents any unwanted shifting or misalignment, which can lead to errors or inconsistencies in the final engraving. By using this custom jig, the user can achieve consistent, accurate results with each use, saving time and reducing material waste while ensuring the highest quality engravings

Designing a jig for your laser cutting projects can dramatically enhance the precision, efficiency, and consistency of your work. A well-designed jig serves as a custom guide, ensuring that each cut or engraving is aligned perfectly, regardless of the complexity of the design or the number of repetitions required. By taking the time to create a thoughtful and durable jig, you can significantly reduce errors, minimize wasted materials, and streamline your production process. This not only saves valuable time and resources but also allows you to focus more on the creative aspects of your projects, ensuring that your final products are consistently high-quality, professional, and beautifully crafted. Whether you’re working on one-off designs or large batch production, investing in a jig can transform your workflow, making your laser cutting experience smoother, more reliable, and ultimately more enjoyable.

Have you designed a jig for your laser cutting projects? Share your experience and tips in the comments below!