Learn how air assist improves your cuts with cleaner edges, fewer scorch marks, faster laser cutting, and safer operation. Includes PSI tips, setup, and troubleshooting.

Introduction

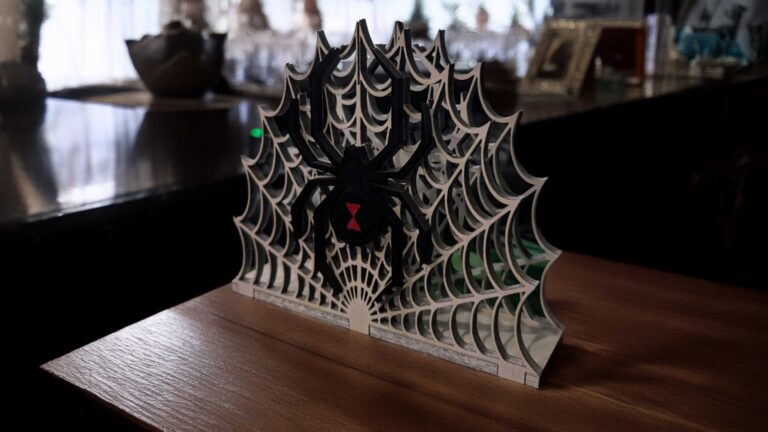

If you’ve spent any time cutting wood, acrylic, leather, or cardboard with your diode or CO2 laser, you’ve probably noticed that the results can vary dramatically depending on one thing: air assist. Whether you’re cutting detailed ornaments, jigs, signs, or thick plywood, air assist is one of the most important upgrades you can make. It improves cut quality, reduces burning, extends laser life, prevents fires, and lets you work faster and cleaner.

In this guide, we’ll break down how air assist improves your cuts, why it works, how to set it up, PSI tips, and troubleshooting.

If you’re new to diode lasers, be sure to read the Diode Laser Beginner Guide as well.

What Is Air Assist in Laser Cutting?

Simple Definition

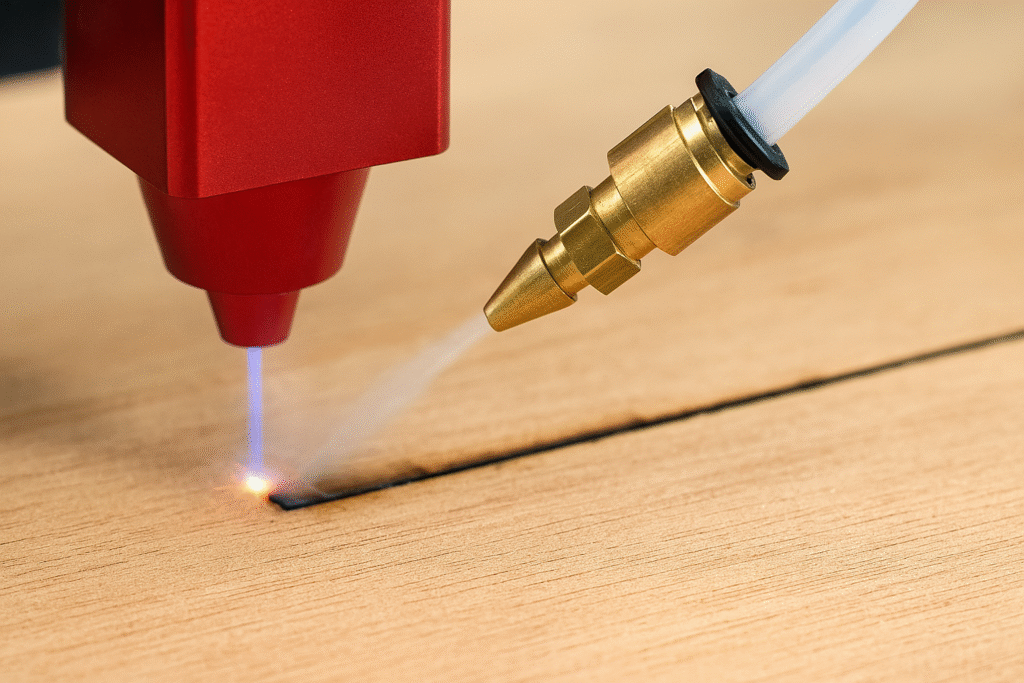

Air assist is a controlled stream of air that blows directly at the point where the laser beam hits your material. This airflow clears debris, smoke, and heat from the cut, dramatically improving quality.

How Air Assist Works

As the laser burns through material, it creates smoke and molten debris (slag). Without airflow, this contaminates the beam path. Air assist removes this instantly so the laser can cut through clean material.

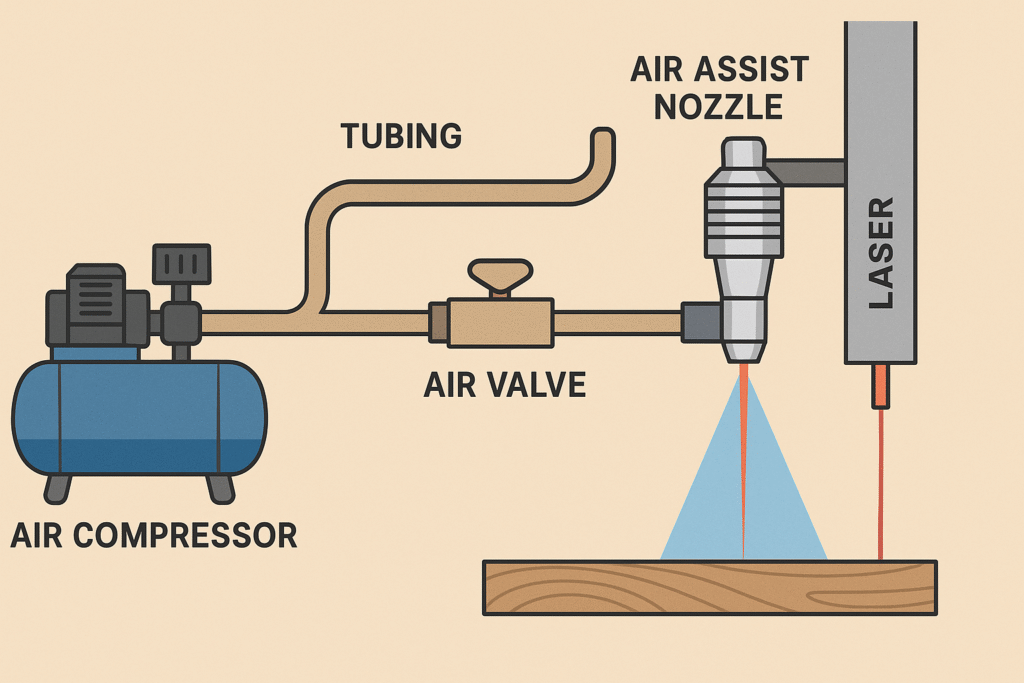

Key Components of an Air Assist System

- Air pump or compressor

- Silicone or PVC tubing

- Metal nozzle

- Air valve or software control

How Air Assist Improves Your Cuts (Core Benefits)

Cleaner Cutting Edges

Smoke staining disappears, edges stay bright, and details remain crisp. Less sanding and less finishing work.

Fewer Scorch Marks and Less Burning

Airflow cools the material and prevents unnecessary burning. Wood projects look cleaner and more professional.

Improves Laser Penetration

Smoke blocks the laser. Removing it increases effective power, enabling fewer passes and deeper cuts.

Faster Cutting Speeds

- Use higher speeds with clean results

- Need fewer passes

- Work more efficiently on production jobs

Prevents Fires

Air assist blows away embers before they develop into flames — crucial for cardboard, cork, and thin materials.

Extends Lens Life

Airflow keeps debris away from the lens, reducing maintenance and extending the life of your machine.

Materials That Benefit the Most From Air Assist

Wood (Plywood, MDF, Basswood)

Cleaner edges, less resin buildup, and stronger parts. Recommended PSI: 20–30 PSI.

Acrylic

Prevents melting, reduces flame-ups, and creates smoother edges.

Leather

Less burn smell, fewer scorch marks, and better detail separation.

Cardboard & Paper

The most flammable materials. Air assist is essential.

Anodized or Coated Metals

Helps with engraving clarity and heat control.

How Much Air Pressure Do You Need? (PSI Guide)

Diode Lasers

Ideal PSI: 15–30 PSI

20 PSI for most wood, 30 PSI for thick plywood, and 10–15 PSI for engraving.

To see how a diode laser handles high airflow, check out the Falcon2 Pro Review.

CO2 Lasers

- Light materials: 10–20 PSI

- Thick acrylic: 40–60 PSI

- Deep cutting: 50+ PSI

Signs You Need More PSI

- Burn marks

- Rounded edges

- Incomplete cuts

- Smoke inside the cut

Signs You Need Less PSI

- Fuzzy edges

- Material movement

- Cloudy acrylic

When to Turn Air Assist Off

High-Detail Engraving

Too much airflow can distort fine details.

IR Laser Heads

Air assist can blow away powder coatings used for IR engraving.

Choosing the Right Air Assist System

Built-In Air Assist

- Quiet and simple

- Lower PSI

- Great for beginners

External Air Compressors

- High PSI

- Strong constant airflow

- Ideal for production cutting

Pump vs. Compressor

- Pump: quiet, low PSI

- Compressor: loud, strong PSI, best for wood

How to Set Up Air Assist Correctly

Positioning the Nozzle

- 2–3 mm above material

- Pointed directly at the burn point

- Avoid extreme side angles

Prevent Air Leaks

- Check tubing connections

- Use tight clamps

- Inspect valves

Software Controls

Use LightBurn or Creality Design Space to toggle air assist automatically during cutting vs. engraving.

Testing & Tuning Air Assist

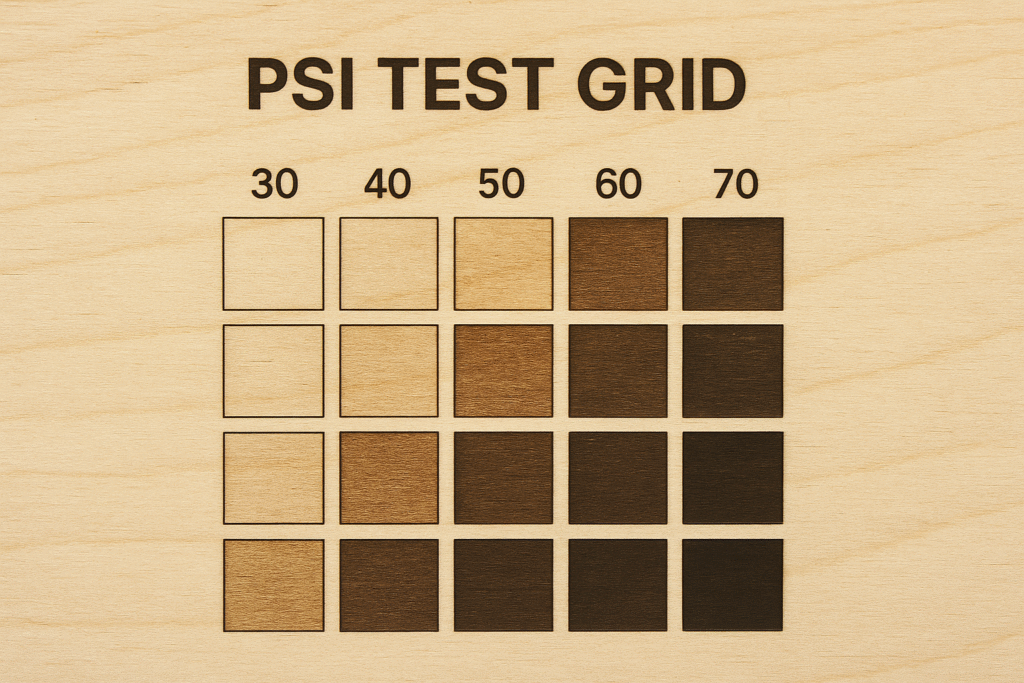

Run a Test Grid

Test different speeds, power levels, and PSI settings.

Tune for Each Material

Wood loves higher PSI. Paper prefers low. Acrylic varies based on thickness.

Compare Before & After

Look for sharper lines, reduced smoke, and cleaner undersides.

Troubleshooting Air Assist Issues

Air Isn’t Turning On

- Software may not be toggled

- Pump or compressor issue

- Loose wiring

Weak Airflow

- Air leaks

- Dirty nozzle

- Damaged tubing

Cuts Still Have Burn Marks

- Increase PSI

- Clean lens

- Check nozzle angle

Safety Benefits of Air Assist

Fire Prevention

Airflow stops small embers from forming flames.

Cleaner Ventilation

Less smoke means better health and less residue inside your machine.

Machine Protection

Air assist keeps debris away from delicate optics.

Frequently Asked Questions

Do I need air assist?

If you cut wood, acrylic, leather, cardboard, or paper — yes.

Can I use an aquarium pump?

Yes, for light cutting and engraving.

Does air assist make my laser more powerful?

No, but it helps your laser act more powerful by clearing smoke.

What PSI should I use for 3mm plywood?

20–25 PSI for clean results.

Does air assist help engravings?

Use low PSI for detailed engravings.

Conclusion: Why Air Assist Improves Your Cuts Every Time

Air assist is a must-have upgrade for anyone cutting with a diode or CO2 laser. It provides cleaner edges, reduces scorching, speeds up cutting, extends machine life, and increases safety.

For more laser cutting tips, check out the Diode Laser Beginner Guide and the Falcon2 Pro Review.