Introduction

In the world of crafting and manufacturing, diode laser engraving stands out as a versatile and precise technique used to create detailed designs on various materials. Whether you are a hobbyist looking to personalize your items or a professional aiming to produce high-quality merchandise, understanding the ins and outs of diode laser engraving is crucial. This blog post will delve deep into what diode laser engraving entails, including the types of lasers used, the materials suitable for engraving, and practical tips to get the best results. Prepare to explore the foundational knowledge needed to embark on your engraving projects, as well as advanced techniques that can elevate your work to professional standards.

Understanding Diode Laser Engraving

The Basics of Diode Lasers

Diode lasers are a type of laser that generates a coherent projection of light through the electrical stimulation of a diode (a semiconductor). In the context of laser engraving, these devices provide a focused beam that can vaporize or melt material on a microscopic scale, allowing for precise and clean cuts or markings. Diode laser engravers are favored for their efficiency and the high level of control they offer users over the engraving process. They are commonly used for small-scale projects in materials like wood, leather, and acrylic.

Types of Diode Lasers

Diode lasers come in various power outputs, typically ranging from 500 milliwatts to over 10 watts. The power level you need depends on the material you intend to engrave and the speed at which you want to work. Lower power lasers (500mW to 2W) are suitable for light materials like balsa wood and thin acrylics, while higher power versions (5W and above) are required for denser materials like hardwood, metals, and thicker plastics. Selecting the right laser is key to achieving optimal results, preventing material damage, and maintaining efficiency in your work.

Preparing for Laser Engraving

Safety First: Precautions and Protective Gear

Safety is paramount when working with laser engraving equipment. Diode lasers, while generally safe when used correctly, can pose risks to eyesight and skin due to direct or scattered laser light. Always wear protective eyewear that specifically blocks or filters the laser wavelength you are using. Additionally, it’s advisable to operate in a well-ventilated area to avoid inhaling any fumes or particles released during engraving. Other protective gear includes fire-resistant gloves and aprons to protect against accidental burns.

Setting Up Your Laser Engraver

Setting up your diode laser engraver involves several key steps to ensure it operates correctly and safely. First, ensure that the engraver is placed on a stable, flat surface away from flammable materials. Alignment of the laser is critical; the beam must be precisely focused on the material’s surface to ensure clean cuts and engravings. Regular maintenance checks, such as cleaning the lenses and checking the alignment, will keep the laser in top working condition and extend its lifespan. Calibration is also crucial, particularly when switching between different types of materials, to adjust the laser’s power settings and focus for optimal results.

Materials Suitable for Diode Laser Engraving

Engraving on Wood

Wood is one of the most popular materials for diode laser engraving due to its natural beauty and ease of engraving. Softwoods like pine and balsa are ideal for beginners because they require lower laser power and provide excellent results. Hardwoods, such as oak and maple, can also be engraved but require higher power settings and slower speeds to achieve clean, deep engravings. Pre-treatment with sanding can smooth the surface and enhance the final result, while post-treatment with oils or varnishes can protect the engraving and bring out the natural grain of the wood.

Engraving on Acrylic and Plastics

Acrylic and certain plastics can be beautifully engraved with a diode laser, creating clear, crisp images and text. It’s important to use cast acrylic rather than extruded, as it produces a white, frosted look that is highly desired for awards and signage. When engraving plastics, it’s essential to know the material composition to avoid engraving materials that could release harmful fumes, such as PVC. Settings for plastics typically involve lower power and higher speed to prevent melting or warping the material.

Engraving on Stainless Steel

When exposed to the intense energy of a high-powered laser beam, the surface of stainless steel undergoes a striking physical transformation. This process, known as laser-induced coloration, activates natural oxide layers on the metal, revealing a vivid palette of colors. As the laser meticulously heats specific areas of your stainless steel piece, it manipulates these oxide layers to produce an array of hues, from subtle pastels to vibrant tones. This technique not only adds a unique visual dimension to your projects but also infuses your work with a dynamic burst of life, making each piece a true reflection of creativity and innovation.”

Other Engravable Materials

Beyond wood, acrylic, and metal, diode lasers can work on materials like leather, paper, fabric, and even stone or coated glass. Each material requires specific settings adjustments and preparation to achieve the best results. For instance, leather should be clean and dry to avoid burning, while paper and fabric should be flat and free from any loose threads or debris.

Techniques and Tips for Effective Engraving

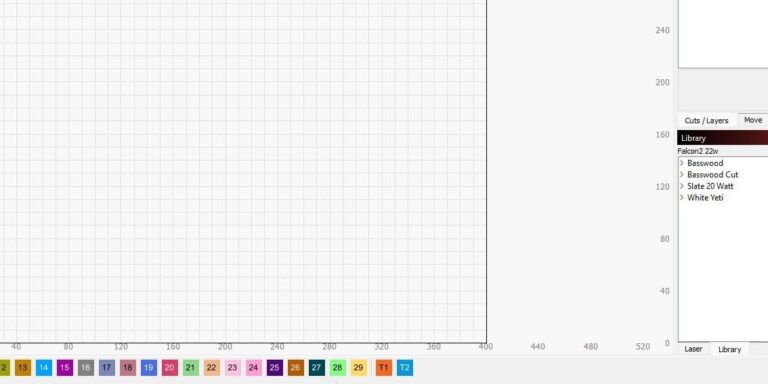

Designing for Engraving

Successful diode laser engraving starts with great design. Software plays a crucial role in this process, with programs like Adobe Illustrator, CorelDRAW, or specialized laser software like LightBurn facilitating the creation and manipulation of designs. When designing for engraving, consider the material and the engraving’s purpose. For example, intricate designs may look fantastic on smooth acrylic but could lose clarity on grainier wood. Vector files are preferred for their scalability and precision, especially for complex patterns and texts.

Troubleshooting Common Issues

Even with careful setup and high-quality equipment, issues can arise during the engraving process. Common problems include incomplete cuts, excessive burning, and unclear images. Many of these can be mitigated by adjusting laser settings like speed, power, and focus. For instance, if the laser is burning wood too deeply, reducing the power or increasing the speed may help. Keeping a log of settings that work well for different materials can serve as a handy reference for future projects.

Advanced Diode Laser Engraving Techniques

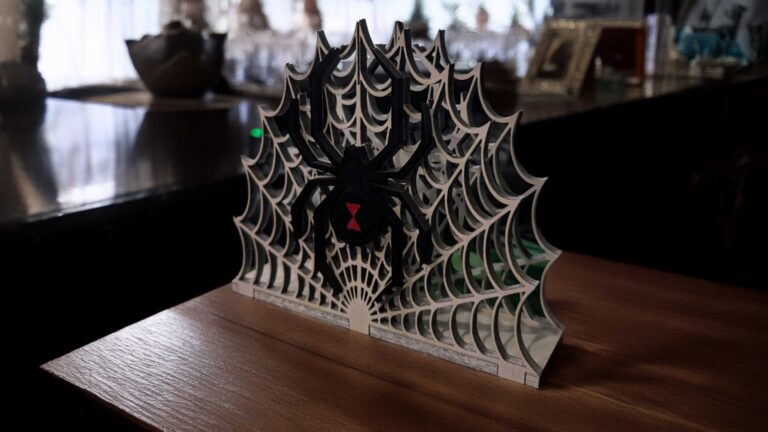

Multi-layer Engraving

Multi-layer engraving is an advanced technique that involves engraving at different depths or removing multiple layers of material to create a 3D effect. This technique can add extraordinary detail and texture to your projects, making them stand out visually. To achieve multi-layer effects, you must carefully plan your design and adjust the laser’s power and speed settings for each layer. Experimenting on scrap material first can help you fine-tune these settings before committing to your final piece.

Color Engraving and Other Innovations

Adding color to laser engravings can dramatically enhance the visual appeal of your projects. While diode lasers don’t directly engrave in color, techniques such as staining wood after engraving or using colored acrylics can create vibrant results. Another innovative approach involves using heat-sensitive materials that change color under the laser’s influence. Additionally, the technology around diode lasers continues to evolve, with new types of lasers and accessories that expand the possibilities of what can be engraved.

Finishing and Protecting Your Engravings

Post-Engraving Finishes

After the engraving process is complete, applying a finish can both protect and enhance the appearance of your project. For wood engravings, options include oils, stains, and varnishes, which can deepen the color and protect against wear and environmental damage. For acrylics, a polish can be applied to the edges to give a clean, professional look. It’s important to choose a finish that is compatible with the material and the intended use of the engraved item.

Enhancing the Visual Appeal of Engraved Items

Beyond the practical aspect of protection, finishes can also enhance the aesthetic appeal of engraved items. Techniques like filling engraved areas with colored resins or waxes can highlight the design and add a touch of elegance. In some cases, combining different materials, such as inlaying wood with metal or acrylic, can produce striking contrasts and make the engraved details pop even more.

Real-World Applications of Diode Laser Engraving

Commercial vs. Hobby Applications

Diode laser engraving isn’t just a hobbyist’s pursuit; it plays a significant role in commercial settings as well. For businesses, laser engraving offers a method to produce consistent, customizable products such as promotional merchandise, serialized items, and personalized gifts. On the hobbyist side, enthusiasts use diode lasers to create unique art pieces, custom decor, and bespoke gifts, leveraging the precision of laser engraving to bring their creative visions to life.

Examples of Commercial Products

In the commercial sphere, diode lasers are used for:

- Branding: Engraving company logos on various merchandise.

- Personalization: Adding names, dates, or unique designs to products like phone cases, jewelry, and kitchenware.

- Serialization: Marking parts and products with serial numbers for tracking and inventory purposes.

Inspirational Projects for Hobbyists

For hobbyists, the possibilities are nearly endless, but some popular projects include:

- Home Decor: Creating customized wall art, photo frames, and mirror decorations.

- Fashion Accessories: Designing personalized leather belts, wallets, and bracelets.

- Gift Items: Crafting one-of-a-kind gifts like engraved pens, cutting boards, and coasters.

Conclusion

Diode laser engraving offers a gateway to both artistic expression and practical application, blending creativity with technology in a way that is accessible to both hobbyists and professionals alike. Understanding the different materials that can be engraved, along with the appropriate techniques and safety measures, can transform your projects from simple crafts to works of art and commercially viable products. As we’ve explored the various facets of diode laser engraving, it’s clear that the key to success lies in meticulous preparation, continuous learning, and creative experimentation.

We encourage you to apply the insights and tips shared in this post to your own engraving endeavors. Whether you are making personalized gifts, creating unique home decor, or producing high-quality commercial merchandise, the world of diode laser engraving is ripe with opportunities to innovate and impress.